What is Job Order Contracting?

Discover how Job Order Contracting streamlines project management and enables faster response times for ongoing construction needs.

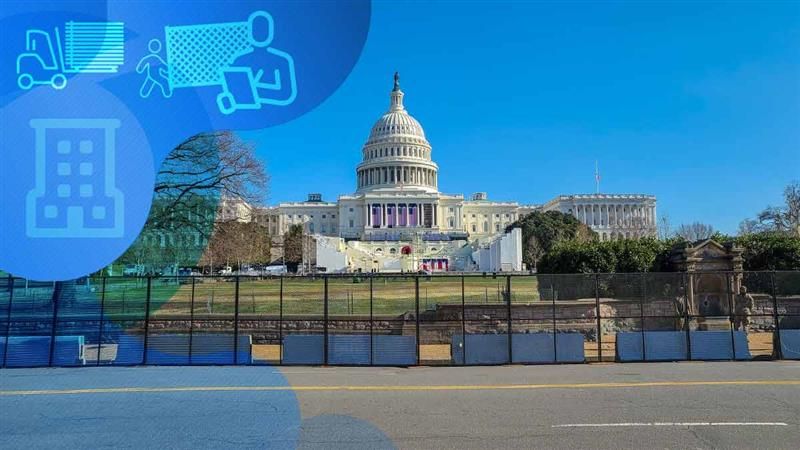

Government agencies and some private companies use the job order contracting (JOC) process to help identify a general contractor to complete repair and maintenance tasks, respond to emergencies, and finish backlogged projects and other ongoing construction needs.

A Master Agreement acts as an umbrella for all projects performed under a JOC. The agreement stipulates the contract's duration (typically, one to two years), with a maximum expenditure cap.

Most governments require potential contractors to undergo a competitive bidding process, which can take months, or even years, to complete. The method is too slow for an urgent job like a broken water main or a leaking roof.

JOC solves the problem by identifying a general contractor through competitive bids. Once a Master Agreement is in place, the general contractor responds to any agency or company requests, up to an established cap.

Since Master Agreements are fixed-price, multi-year contracts, contractors must understand the process to ensure they are fairly compensated for the work performed. That means including escalation clauses to allow for increases in labor and material costs and establishing an adjustment factor based on a unit price book (UPB).

How Does Job Order Contracting Work?

As with any competitive bidding process, the construction JOC process begins when a company or agency solicits bids from local contractors for specified tasks detailed in a UPB.

What is a UPB?

A UPB or Unit Price Book is a catalog of construction unit prices. It may be localized or it could reference one of the standard UPBs, which lists every industry-standard construction task and a unit price.

For example, Installing Temporary Fence may appear as a line item with a unit price based on putting up one linear foot of temporary fence. Under the title is a description and a list of the materials, equipment, and labor costs associated with the task.

The UPB size varies from less than 10,000 line items to more than 100,000. Any tasks outside of the pre-priced UPB items must follow all solicitation requirements. In the case of government agencies, the non-pre-priced items must be sent out for competitive bids.

Responding to a Request for Bids

The solicitation request lists the specific tasks to be included in the Master Agreement. Contractors look up the unit price for all listed tasks in the UPB. For tasks that are not pre-priced, the contractor proposes a price.

Because UPBs use standardized pricing, contractors can submit an adjustment factor to more closely match costs in their local market. The unit price is multiplied by the adjustment factor to arrive at a localized price. An adjustment factor of one means that the contractor accepts the unit pricing listed in the UPB. A factor of less than one lowers the price, while a factor greater than one increases the cost.

Creating the Master Agreement

Once a contractor is selected, the organization creates a master agreement outlining the contract's length and the maximum value. As part of the creation process, contractors may ask for price-escalation clauses that allow for unexpected increases in labor and material costs.

With a master agreement in place, contractors can execute multiple projects simultaneously -- as long as they remain within the contract amount, are within the authorized timeframe, and have approval.

Beginning Work

As tasks are assigned, the general contractor, facility manager, or designated party tours the work site. They discuss and document the scope of work. Every task should have a separate order, even if discussed during the same walkthrough. After the joint scope review, the general contractor prepares the task orders.

Developing a Task Order

General contractors should have a system for tracking task orders against a master agreement. Sometimes, they may need to use an issuing organization's system. Regardless of the system, the general contractor should:

- Identify the appropriate line items from the UPB.

- Multiply the number of work units by the UPB price.

- Multiply the task costs by the adjustment factor, if any.

Before submitting the order for approval, the contractor should confirm subcontractor pricing and identify non-pre-priced work.

Obtaining Subcontractor Bids

General contractors may request bids from subcontractors during the bidding process or wait until a task is being developed before asking for pricing. If they estimate subcontractor costs during bidding, they will need to solicit bids to confirm that the proposed price is still valid.

If they receive subcontractor pricing during the proposal phase, general contractors should confirm the proposed pricing.

Preparing Non-Pre-Priced Bids

Sometimes, tasks require work that is not provided in a UPB. In such cases, general contractors should identify the non-pre-priced work during the walkthrough. They should also request bids from subcontractors or price the work if it is done in-house. The cost for the non-pre-priced work should be submitted to the organization for approval before being incorporated into the task order.

Receiving Approval

General contractors incorporate all pricing into a single task order and submit it to the organization for approval. Scheduling may accompany the task order or be agreed on separately. Once approval is received, work can begin.

As work commences, general contractors should ensure clear communication among all parties. They should notify the issuing organizations of potential delays or material shortages and update subcontractors on status changes to ensure that resources will be available when needed.

Finishing Work

General contractors can invoice when a task order is complete. They may even use progress billing if a task has a lengthy completion time. However, per-task billing can be challenging unless the general contractor is well-organized. These steps will make for a smoother billing process:

Establish Task Order Monitoring

Tasks may overlap. For example, a long-term roofing project is projected to take three months. Simultaneously, a task order is issued to repair leaking pipes. One month after the roof repairs start, the facility manager needs an empty room upgraded so it can be used. Without a monitoring system, general contractors may struggle to keep track of overlapping projects.

Developing a numbering system to identify each task under a master agreement makes it easier to track its progress. Subcontractors should use the same system when submitting invoices. For example, plumbing subcontractors should submit their costs for repairing leaky pipes under one task number. They should then use a different task number to bill for the work in the upgraded room.

Billing by task number allows general contractors to invoice the issuing organization as work is completed. It also lets them pay subcontractors promptly and cover equipment and material costs. This is very important to maintain positive cash flow.

Maintain Work Logs

Work logs should be maintained per task. The plumbers should use the task order number to identify who worked on the leaky pipes. Even if the room upgrade work occurred on the same day, the work log should show the effort that went into that task.

Keeping records helps keep JOC projects running smoothly. It allows the issuing organization to stay informed, prevents unnecessary payment delays, and facilitates better working relationships with subcontractors. Comprehensive documentation can quickly resolve conflicts should they arise.

Why Consider Job Order Contracting?

JOC is a unique working arrangement in the construction industry. Contractors and organizations can benefit from the process if they understand the requirements and workflows.

Contractor Benefits

Both GCs and subcontractors benefit from the process, as longer-term contracts provide predictable income. For general contractors, using the same suppliers, subcontractors and staff for multiple tasks establishes a smoother working relationship for faster delivery and improved outcomes.

Understanding the JOC process allows general contractors to develop better pricing strategies that ensure profitability. These strategies can be carried over to other construction projects for better profit margins. Relationships developed under JOC create added resources for contractors.

Organization Benefits

Perhaps the most significant benefit for issuing organizations is access to construction resources during emergencies. If a hurricane or tornado tears a roof off a city building, the local government can get repairs started immediately. No waiting for a proposal to be written or bids to be submitted.

Government agencies and private companies develop trusting relationships with their JOC businesses, making it easier to complete repairs or renovations as needed. The defined process allows organizations to align efforts to meet local needs.

How to Be a Successful JOC Business?

To give JOC meaning, general contractors should establish repeatable processes. Breaking up tasks into repetitive smaller tasks simplifies the process, making it easier to implement efficient workflows.

- Documentation. Numerous projects at varying scales can become overwhelming without clear documentation. Successful JOC companies have mastered an efficient documentation process.

- Details. General contractors should not assume they understand an organization's requirements. They should take time to read and understand the details outlined in the solicitation.

- Communication. Successful contractors communicate clearly and continuously with all parties. They keep all stakeholders informed to minimize friction and resolve conflicts before they become obstacles.

Successful general contractors are also prepared. They must have knowledge of federal and local building codes, ensuring compliance and worker safety with every task performed.

When construction tasks are high-risk, using the right construction safety equipment is essential. Learn more about different types of PPE and how to determine what you need for each project by reading our recent article!

Trend now

Theme Park Safety: Avoiding Fines and Accidents with Crowd Control

Learn how crowd control products help keep theme parks safe, avoid accidents, and improve operations. Explore SONCO’s solutions for better crowd management.

Anti Scale Fence for Temporary High-Security Needs

Anti scale fence designed for temporary high-security perimeters, crowd control, protests, and emergency response where standard fencing falls short.

Why Bike Rack Barricades Are the Go-To Choice for Crowd Control

Explore why bike rack barricades are the go-to for crowd control. Learn how these versatile, durable barriers keep events, construction sites, and more organized.