What Is a Chain Link Fence? Types, Materials, Costs & Applications

Learn about chain link fence types, pricing, gauge, and applications. Compare galvanized and PVC options and find the right fencing system.

A chain link fence is one of the most common and practical fencing options used today. You’ll see it around homes, construction sites, sports fields, warehouses, and event spaces. It’s known for being strong, affordable, and easy to install.

In this guide, you’ll learn what a chain link fence is, how it’s built, the different types available, and when it makes sense to use one.

What Is a Chain Link Fence?

A chain link fence is a type of fence made from interwoven steel wires that form a diamond pattern. The wires are bent and linked together to create a strong, flexible mesh that is attached to metal posts and rails.

Chain link fences are used to create secure boundaries for homes, businesses, construction sites, sports fields, and temporary perimeters. They are valued for their durability, visibility, and cost effectiveness compared to other fencing materials.

How Are Chain Link Fence Panels Built?

Panel systems are common for temporary fencing, construction sites, and event perimeters because they are fast to install, remove, and relocate.

Most portable chain link fence panels are 6 feet tall and available in widths of 8, 10, 12, or 14 feet. This range makes it easier to adjust the perimeter based on the size and shape of the space.

Main Components of a Chain Link Fence Panel

Each panel typically includes:

- Four steel tubes that form the outer frame

- Welded corner joints that hold the frame together

- Optional vertical or cross braces for added strength

- Chain link mesh stretched tightly across the frame

- Metal tie wires that secure the mesh to the rails

- Vertical tension bars and bands that keep the fabric in place

Multiple panels are connected side by side to create a continuous perimeter.

Benefits of Chain Link Fences

Chain link fences are popular because they offer a balance of durability, affordability, and flexibility. They are used in residential, commercial, and industrial settings for both permanent and temporary boundaries.

Key benefits include:

- Affordable

Chain link fencing is usually less expensive than wood, vinyl, or ornamental metal fencing.

- Durable

Galvanized and PVC-coated options resist rust and handle long-term outdoor exposure.

- Low maintenance

Unlike wood, chain link does not need painting or sealing and requires minimal upkeep.

- Fast to install

Panels and roll systems can be installed quickly, making them practical for jobsites and event setups.

- Reusable and modular

Temporary panel systems can be removed, relocated, and reconfigured as needed.

- Open visibility

The diamond mesh design allows airflow and visibility, which is useful for security monitoring.

Pros and Cons of Chain Link Fencing

Pros

- Cost effective

- Long lifespan with proper coating

- Easy to repair

- Works for many applications

Cons

- Limited privacy unless slats or screens are added

- More industrial appearance than decorative fencing

- Lower gauge wire can bend under impact

How Much Does a Chain Link Fence Cost?

The cost of a chain link fence depends on the height, wire thickness, coating type, and whether it is installed permanently or used as temporary panels.

On average, a permanently installed chain link fence costs between $8 and $40 per linear foot, including materials and labor. Basic galvanized fencing sits at the lower end of the range, while taller fences, heavier gauge wire, privacy slats, and PVC coatings increase the price.

For temporary chain link fence panels, pricing is different. Panels are typically sold by the section rather than by the linear foot, and costs vary based on size, frame strength, and finish. Rental pricing is usually calculated per panel and per day or week.

Several factors affect the final cost:

- Fence height

- Wire gauge thickness

- Galvanized vs PVC coating

- Gates and accessories

- Ground conditions and terrain

- Labor rates in your area

Heavier gauge wire and hot dip galvanized finishes cost more upfront but typically last longer and reduce long term maintenance costs.

Typical Chain Link Fence Cost by Type

FENCE TYPE

RELATIVE COST

TYPICAL USE

LIFESPAN

Pre galvanized steel

Low

Light duty or short term use

5 to 15 years

Hot dip galvanized steel

Medium

Residential, commercial, security

20 to 50+ years

PVC coated chain link

Medium to High

Residential, aesthetic or corrosion prone areas

15 to 30 years

Chain Link Fence Applications

Chain link fencing is used in residential, commercial, industrial, and temporary settings. Its strength, visibility, and affordability make it a practical choice for many types of properties.

Residential Use

Homeowners use chain link fences to enclose backyards, secure pets, define property lines, and create pool enclosures. The open mesh design allows airflow and visibility while still providing a secure boundary.

Commercial and Institutional Use

Businesses and institutions rely on chain link fencing to protect property and control access. Common applications include:

- Warehouses and storage yards

- Schools and universities

- Hospitals and medical facilities

- Parking lots and municipal buildings

In these environments, durability and clear sight lines are important.

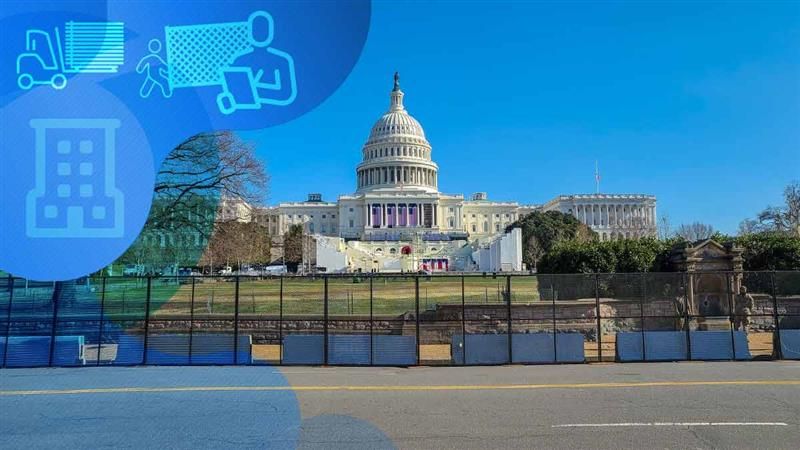

Construction and Temporary Use

On construction sites and active job sites, chain link panels create temporary perimeters. They help control access, protect materials, and improve overall site safety.

Temporary chain link fencing is also widely used for:

- Concerts and festivals

- Sporting events

- Public gatherings

- Crowd control setups

Panels are easy to install, remove, and reposition as project needs change.

Sports and Public Infrastructure

Chain link fencing is commonly installed around sports fields, tennis courts, playgrounds, and public parks. It provides a durable boundary while allowing spectators and staff to maintain visibility.

It is also used in transportation settings such as airports, rail facilities, and highway perimeters where long term security fencing is required.

High Security Applications

Heavier gauge wire and taller chain link systems are used in higher security environments such as:

- Airports

- Utility facilities

- Data centers

- Government buildings

Additional features like privacy slats, anti climb mesh, or extended height can increase perimeter protection.

Types of Chain Link Fence

Chain link fencing is available in different finishes and configurations. The main differences affect durability, appearance, and long term performance.

Pre Galvanized Chain Link

Pre galvanized chain link is coated with a thin layer of zinc before the fencing is manufactured. This provides basic protection against rust and corrosion.

It is usually the most affordable option and is commonly used for light duty or short term applications. Over time, exposure to weather and surface damage can reduce its corrosion resistance.

Hot Dip Galvanized Chain Link

Hot dip galvanized fencing is coated after fabrication by immersing the steel frame and mesh in molten zinc. This process creates a thicker protective layer.

It offers higher durability and stronger corrosion resistance compared to pre galvanized fencing. Hot dip galvanized chain link is often chosen for residential, commercial, and security applications where long term performance is important.

PVC Coated Chain Link

PVC coated chain link uses a vinyl layer over galvanized steel. The coating adds extra protection from moisture and environmental exposure.

It is available in colors such as black or green, which can provide a more finished appearance. PVC coated fencing is commonly used in residential areas, schools, parks, and facilities where appearance matters along with durability.

Slatted Chain Link

Slatted chain link includes plastic, aluminum, or other inserts placed within the mesh. These inserts increase privacy and reduce visibility through the fence.

Slatted fencing is used in areas where privacy, wind reduction, or visual screening is needed without switching to a completely solid fence system.

Chain Link Fence Gauge Explained

The gauge of a chain link fence refers to the thickness of the wire used to create the mesh. Lower gauge numbers mean thicker and stronger wire.

Choosing the right gauge depends on how the fence will be used.

Common Chain Link Fence Gauges

GAUGE

THICKNESS LEVEL

TYPICAL USE

9 gauge

Heavy duty

Commercial and high security fencing

11 gauge

Standard strength

Residential and general perimeter fencing

12.5 to 13 gauge

Light duty

Temporary or lower impact areas

16 to 17 gauge

Lightweight

Very light or short term use

Thicker wire provides greater resistance to bending and impact. Heavier gauges are commonly used in commercial, institutional, and higher security settings.

For residential properties or areas with minimal impact risk, standard gauge options are often sufficient.

How to Install a Chain Link Fence

Setting up a chain link fence can be done as a permanent system with posts set in concrete or as a temporary panel installation. The installation process depends on the type of fence and the site conditions.

Basic Steps for Permanent Installation

- Plan the fence layout and measure the perimeter.

- Mark post locations and dig holes based on local depth requirements.

- Set terminal posts and line posts in concrete and allow them to cure.

- Attach horizontal rails between posts.

- Unroll the chain link fabric and secure it to the posts and rails using tension bars and bands.

- Stretch the mesh tightly before fastening it to prevent sagging.

Proper alignment and tension are important for long term durability.

Temporary Panel Installation

Temporary chain link panels do not require posts set in the ground. Instead:

- Place fence bases on level ground.

- Insert panels into the base supports.

- Connect panels together using couplers or clamps.

- Add gates or bracing if needed.

Panel systems are faster to install and remove, which makes them common for construction sites and event perimeters.

Local regulations and safety requirements may vary, so installation guidelines should always be verified before starting a project.

Frequently Asked Questions About Chain Link Fences

How long does a chain link fence last?

The lifespan depends on the finish and environment. Pre galvanized fencing may last 5 to 15 years, while hot dip galvanized systems can last 20 to 50 years or more. PVC coated options typically fall between 15 and 30 years.

What is the strongest type of chain link fence?

Lower gauge wire provides greater strength. Nine gauge and hot dip galvanized chain link fencing are commonly used in higher security or commercial applications.

Is chain link fencing cheaper than wood?

In most cases, chain link fencing costs less than wood fencing, especially when considering long term maintenance. Wood requires staining or sealing over time, while chain link typically needs minimal upkeep.

Can chain link fences rust?

Basic galvanized fencing can rust over time if the protective coating wears down. Hot dip galvanized and PVC coated fencing provide stronger corrosion resistance.

What height chain link fence is most common?

For residential use, 4 to 6 feet is common. Commercial and industrial fencing often ranges from 6 to 12 feet depending on security requirements.

Can chain link fences be used temporarily?

Yes. Pre assembled panel systems allow chain link fencing to be installed and removed without permanent posts, making it suitable for construction sites and events.

Chain Link Temporary and Post Driven Fence from SONCO

SONCO supplies both chain link temporary fence panels and post driven chain link fence systems, with ready stock available for fast shipping and on time delivery.

With nationwide inventory and dedicated account managers, we support construction projects, events, and rental operations that require reliable material flow and clear communication.

From large job sites to short term perimeter setups, our team works to keep your fencing needs organized and moving on schedule.

Trend now

Theme Park Safety: Avoiding Fines and Accidents with Crowd Control

Learn how crowd control products help keep theme parks safe, avoid accidents, and improve operations. Explore SONCO’s solutions for better crowd management.

Anti Scale Fence for Temporary High-Security Needs

Anti scale fence designed for temporary high-security perimeters, crowd control, protests, and emergency response where standard fencing falls short.

Why Bike Rack Barricades Are the Go-To Choice for Crowd Control

Explore why bike rack barricades are the go-to for crowd control. Learn how these versatile, durable barriers keep events, construction sites, and more organized.