Traffic Paint: The Facts Behind Fading and Compliance

Traffic paint fades fast when it’s not built for the job. Learn what affects durability, how rules apply, and how SONCO helps keep markings bright and lasting.

Most property managers, contractors, and municipalities lose money every year by ignoring pavement visibility.

When traffic paint wears out too soon, it leads to confusion, accidents, and early maintenance costs that add up fast.

The truth is, faded lines don’t just look bad, they affect safety and compliance. From parking lots to city streets, poor markings mean:

- More time spent re-striping

- Complaints from drivers or inspectors

- Risk of non-compliance with ADA or DOT rules

And that’s before you count the cost of stopping operations to repaint.

The Problem: When Faded Traffic Paint Create Hidden Costs

When traffic paint fades, it’s not just an aesthetic problem, it affects safety, schedules, and reputation.

That means more than re-striping, it means losing time, money, and trust.

Who It Affects

What Happens

Why It Matters

Contractors

Re-striping before expected

Lost hours, lower profit, fewer new bids

Paving Crews

Confusing or unsafe work zones

Slower workflows and more jobsite risks

Municipal Teams

Complaints and accidents from poor visibility

Public pressure and liability exposure

Property Managers

Faded ADA or fire lanes

Fines and legal consequences

According to SONCO’s specialist in traffic marking solutions, contractors can’t afford to experiment on the job:

“Contractors don’t have time to test different paints. They need materials that work the first time, fast-drying, compliant, and ready to roll. That’s what we focus on every day.”

What Data and Regulations Say

According to the Transportation Research Board, well-maintained road markings can reduce crashes by up to 21%.

The Federal Highway Administration (FHWA) estimates that U.S. agencies spend nearly $2 billion every year repainting lines that fade too soon.

Those numbers prove that marking visibility isn’t optional, it’s part of safety performance.

Two major regulations set the standard for compliance:

Requires maintaining minimum retroreflectivity for all road markings.

Mandates clear, visible markings for accessible parking spaces and access aisles.

Together, they define how long traffic paint must perform and when it’s time to reapply.

Using the right paint from the start keeps projects compliant and cuts maintenance costs over time.

The Challenge: Choosing the Right Traffic Paint for Every Surface

One of the hardest calls on any project is choosing the right traffic paint. Use the wrong type, and you’ll be back re-striping before the quarter ends.

Each has a purpose. The problem starts when it’s used outside of it.

Common Mistake

Result

Using water-based pavement paint on high-traffic roads

Fades quickly under constant tire wear

Applying thermoplastic paint to low-traffic lots

Unnecessary cost and labor time

Skipping surface cleaning and prep

Poor adhesion and early peeling

Ignoring weather and temperature during application

Cracking or uneven curing

Buying non-DOT compliant paint

Failed inspections and repeat work

What Professionals Need to Work Efficiently

Every project depends on time, precision, and durability.

Crews need job-ready materials that make work faster, safer, and easier to maintain.

They need:

- Efficiency

Paints that dry fast, reducing downtime and keeping schedules on track.

- Reliability

Long-lasting pavement marking paint that stands up to weather, sunlight, and heavy use.

- Job-Ready Materials

5-gallon containers that are easy to load, pour, and apply with standard equipment.

- Traffic Control Equipment

Cones, barriers, and signage to keep the work area safe and professional.

Traffic Paint Designed for Real-World Performance

Not every project needs the same type of traffic paint. The right choice depends on the surface, traffic volume, and exposure.

Water-Based Pavement Paint

Perfect for parking lots, warehouses, and low-traffic areas.

- Fast-drying and low-VOC.

- Easy cleanup, great for quick maintenance cycles.

- Compliant with most city and state specs.

Thermoplastic Road Marking Paint

Built for highways, intersections, and heavy-traffic zones.

- Long-lasting visibility and retroreflectivity.

- Withstands high heat and tire wear.

- Meets or exceeds DOT standards.

From Paint to Equipment — SONCO Has You Covered

With over 45 years of experience supporting contractors, municipalities, and property managers, SONCO understands how small decisions, like paint selection, can impact safety and budget in the long run.

Our team provides:

- DOT-compliant products that meet the latest regulations.

- Guidance on material selection for your traffic and surface type.

- Reliable support before and after purchase.

- Fast, nationwide delivery from multiple warehouse locations.

“For us, it’s not about selling paint. It’s about helping crews finish safer, faster, and with confidence that the markings will last through the season.”

— SONCO Specialist

SONCO delivers what professionals need to keep their sites visible, compliant, and safe.

Reach out today by emailing sales@soncostore.com or calling 866-254-6510.

Trend now

Theme Park Safety: Avoiding Fines and Accidents with Crowd Control

Learn how crowd control products help keep theme parks safe, avoid accidents, and improve operations. Explore SONCO’s solutions for better crowd management.

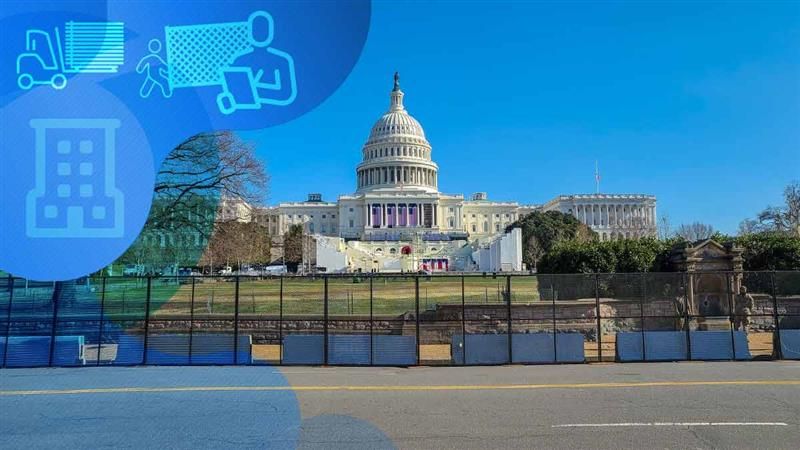

Anti Scale Fence for Temporary High-Security Needs

Anti scale fence designed for temporary high-security perimeters, crowd control, protests, and emergency response where standard fencing falls short.

Why Bike Rack Barricades Are the Go-To Choice for Crowd Control

Explore why bike rack barricades are the go-to for crowd control. Learn how these versatile, durable barriers keep events, construction sites, and more organized.