Sand Shortage: Causes, Impacts, and Effects on Construction

Sand shortage is affecting construction costs and material supply. Learn the causes, impacts, and practical site-level alternatives contractors are using.

A sand shortage does not mean the world is running out of sand entirely. It means we are running short on the specific type of sand required for construction, concrete production, and infrastructure development.

Construction-grade sand is essential for buildings, roads, bridges, and glass manufacturing. As global construction activity increases, demand for this material continues to rise faster than natural replenishment rates in many regions.

The sand shortage has begun to impact project costs, supply chains, and long-term sustainability in the construction industry. Understanding its causes and effects is critical for contractors, developers, and infrastructure planners.

What Is a Sand Shortage?

A sand shortage refers to a supply imbalance between the demand for construction-grade sand and the amount that can be sustainably extracted.

Not all sand is suitable for construction. Desert sand, for example, has rounded grains shaped by wind erosion, which makes it too smooth to bind effectively in concrete. Construction sand typically comes from rivers, lakes, coastlines, and quarries, where the grain texture allows it to bond properly with cement and aggregates.

As global construction demand increases, the extraction of this specific type of sand often outpaces natural replenishment rates. This creates pressure on supply chains and raises concerns about long-term availability.

The issue is not the total volume of sand on the planet, but the limited supply of sand that meets engineering and structural requirements.

Why Is There a Global Sand Shortage?

The sand shortage is driven by rising demand and limited natural supply.

According to the United Nations Environment Programme (UNEP), global sand extraction is increasing by about 6% each year, a rate considered unsustainable. Tens of billions of tonnes are removed annually for construction, infrastructure, and industry.

In many regions, sand is being extracted much faster than it can naturally regenerate. This imbalance is what creates the current sand shortage.

Global attention to the issue grew in 2019 when UNEP released its Sand and Sustainability report, outlining the environmental risks of over-extraction and recommending more sustainable management practices.

Rapid Urbanization

Growing cities require large volumes of concrete for housing, roads, bridges, and commercial buildings. Concrete depends heavily on construction-grade sand, making urban expansion one of the main drivers of demand.

Global construction spending has continued to increase in recent years, putting additional pressure on raw material supply chains. As infrastructure projects expand, sand consumption rises with them.

Infrastructure and Transportation Projects

Highways, airports, ports, and public works projects consume massive amounts of sand-based materials. Large-scale government investments in infrastructure further accelerate extraction rates.

Sand is not only used in concrete. It is also a key component in asphalt, glass, and drainage systems.

Industrial and Manufacturing Use

Beyond construction, sand is essential in:

- Glass manufacturing

- Electronics and silicon production

- Water filtration systems

- Foundries and metal casting

This diversified use increases global demand even when construction activity slows.

Slow Natural Replenishment

While sand forms naturally through erosion, it does so over very long geological timelines. In many regions, extraction happens much faster than natural replenishment, especially in riverbeds and coastal environments.

This imbalance between extraction and regeneration is what turns high demand into a sand shortage.

How the Sand Shortage Affects the Construction Industry

The sand shortage is not only an environmental issue. It has operational and financial consequences for construction projects.

Rising Material Costs

As supply tightens, the price of construction sand and related materials increases. Higher raw material costs affect:

- Concrete production

- Asphalt mixes

- Glass and building components

In some regions, construction input costs have risen significantly in recent years, partly due to pressure on aggregates and raw materials.

When material prices fluctuate, contractors face tighter margins and more unpredictable budgeting.

Project Delays

Limited supply can slow down large infrastructure and commercial developments. When materials are harder to source, lead times increase and project schedules may shift.

Delays impact labor allocation, equipment planning, and client expectations.

Increased Environmental and Regulatory Pressure

Over-extraction of sand from rivers and coastal areas has led to stricter environmental regulations in many countries. While these regulations aim to protect ecosystems, they can further restrict supply.

This adds complexity to sourcing approved materials for large-scale construction projects.

Shift Toward Alternatives

As costs and regulations tighten, builders are exploring:

- Recycled aggregates

- Alternative fill materials

- Modular systems requiring less raw material

Long-Term Industry Responses to Sand Scarcity

The sand shortage is pushing the construction industry to rethink material use, sourcing, and design practices. Instead of relying on a single raw material, companies are adopting more diversified approaches.

Increased Use of Recycled Materials

Recycled concrete, crushed aggregates, and reclaimed materials are being used more frequently in construction projects. These materials help reduce pressure on natural sand extraction while maintaining structural performance in many applications.

Recycling initiatives are also becoming more common in urban demolition and redevelopment projects.

Alternative Aggregate Development

Engineers are studying manufactured sand and other engineered aggregates that can replace natural sand in certain uses. While not always a complete substitute, these materials can reduce overall demand.

Advancements in processing technologies are making alternative aggregates more viable in specific markets.

Smarter Material Planning

Contractors and project managers are focusing more on:

- Material efficiency

- Precise quantity forecasting

- Reducing waste on-site

- Improving logistics coordination

Better planning reduces unnecessary over-ordering and storage losses.

Design Adjustments and Modular Systems

Some projects are incorporating modular barriers, prefabricated systems, and alternative ballast solutions that rely less on sand-based materials.

These adaptations do not eliminate sand use entirely, but they reduce dependency in certain phases of construction.

Alternatives to Sandbags in Construction Applications

Sandbags have long been used for temporary ballast, containment, and perimeter stabilization on construction sites. However, heavy dependence on sand-based solutions can create logistical and material challenges as supply pressures increase.

Traditional sandbags also require:

- Transporting large volumes of fill

- On-site labor for filling and placement

- Disposal or storage after use

- Continuous replacement over time

Because of these limitations, many construction teams evaluate reusable ballast systems that do not rely on loose sand.

Reusable Anchor Base Systems

Pre-engineered anchor bases provide stabilized support for temporary fence panels and barriers without requiring filled sandbags.

Instead of relying on bulk sand delivery and manual filling, these systems:

- Arrive ready to deploy

- Reduce labor on site

- Can be reused across multiple projects

- Simplify transport and storage

For projects where temporary fencing and perimeter control are required, reusable anchor systems reduce dependence on loose aggregate materials while improving operational efficiency.

How SONCO Supports Contractors Facing Material Challenges

For 50 years, SONCO has supplied safety and perimeter control products to construction teams across the United States.

As material availability and costs continue to fluctuate, many contractors are evaluating more predictable and reusable jobsite solutions.

SONCO’s Anchor Base family provides stabilization for temporary fencing without relying on loose sand or disposable ballast.

These systems are:

- In stock and ready to ship

- Designed for repeated use

- Compatible with standard temporary fence panels

- Suitable for active construction environments

For teams looking to reduce labor, simplify logistics, and minimize material waste on site, reusable ballast systems offer a practical alternative.

If your projects involve temporary fencing or perimeter stabilization, you can contact our team to discuss available configurations and shipping timelines.

Trend now

Theme Park Safety: Avoiding Fines and Accidents with Crowd Control

Learn how crowd control products help keep theme parks safe, avoid accidents, and improve operations. Explore SONCO’s solutions for better crowd management.

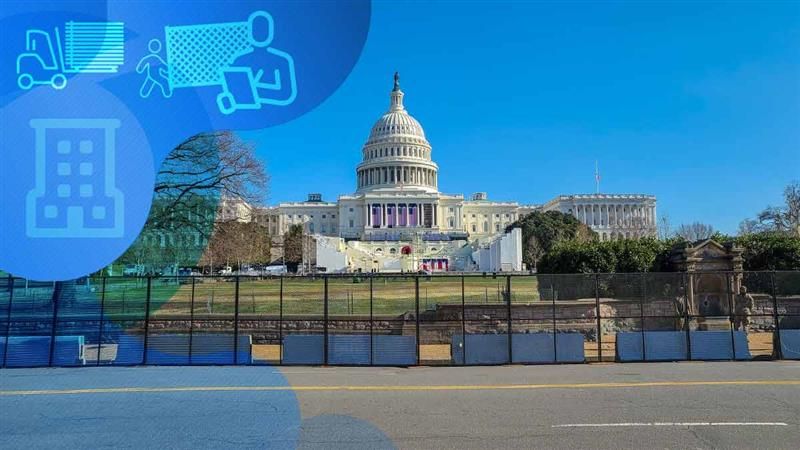

Anti Scale Fence for Temporary High-Security Needs

Anti scale fence designed for temporary high-security perimeters, crowd control, protests, and emergency response where standard fencing falls short.

Why Bike Rack Barricades Are the Go-To Choice for Crowd Control

Explore why bike rack barricades are the go-to for crowd control. Learn how these versatile, durable barriers keep events, construction sites, and more organized.