4 Common Mistakes Buyers Make When Buying Steel Barricades

Avoid These Top 4 Common Mistakes When Buying a Metal Barricade

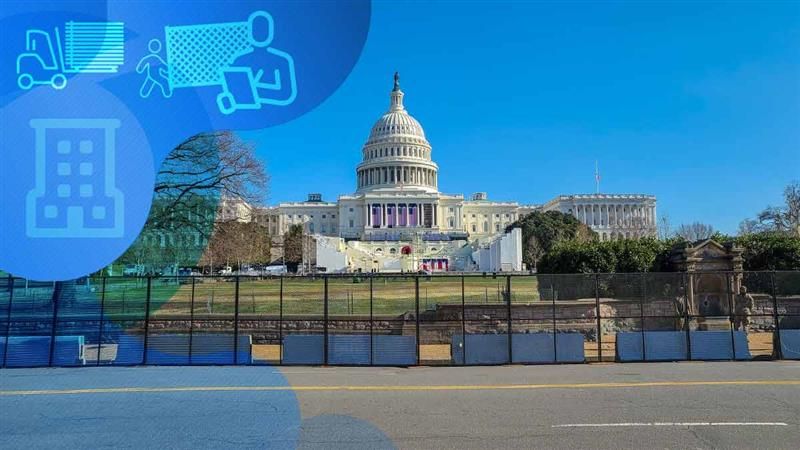

When it’s time to buy steel barricades for venues, events or job sites, SONCO offers customization features that solve the most pressing safety problems.

A premium quality metal barriers is built from superior materials and rigorously tested for safety and regulatory compliance, but it’s tempting to buy cheap products when budgets are tight!

Unfortunately, sub-standard barricades can increase safety risks to employees and the general public. Buying the wrong kind of bike rack barricade could also lead to reputation damage while leaving you vulnerable to costly lawsuits.

Mistake 1: Overlooking Barricade Finish

Pre-galvanized barricades are coated lightly in zinc before construction, and they are often a good choice for infrequent use or indoor venue setups.

The lighter-duty galvanization process does not provide the same corrosion resistant finish as hot-dipping. Unfortunately, some SONCO competitors market these pre-galvanized steel products for outdoor events and roadwork or construction sites – and we would not recommend this.

When a pre-galvanized metal barricade encounters outdoor precipitation, humidity or routine moisture during use or storage, it lacks the robust protection supplied by zinc hot dipping. You need durable barrier systems for outdoor use and heavy crowds, so we recommend protecting your investment with hot-dip galvanized finishes.

Process & Benefits of Hot Dip Galvanized Steel Finish

The hot-dipping process is nearly two centuries old. Invented in France, this time-honored finishing method helps guarantee SONCO’s impeccable product quality.

- Before your galvanized steel barricade is dipped, SONCO manufacturing technicians clean and inspect it. Every bike rack barrier must meet our ambitious quality standards before it is approved for finishing.

- During the hot dip galvanization process, we immerse steel bike rack barricades in an 850 degree molten zinc bath. Dipping causes a chemical reaction, depositing three base layers of zinc-iron alloy and one top layer of pure zinc onto the product.

- Zinc dipping produces steel-strong barricades that are rust and corrosion resistant – for up to seven(!) decades, according to the American Galvanizers Association. Your investment is secure, and you can use your steel barrier system inside or outside, again and again.

Mistake 2: Not Understanding How Tube Gauge Affects Barricade Longevity

It may seem backward, but lower numbers mean thicker steel when it comes to the gauge measurement. For example, 18-gauge steel is 0.0478” thick, while 16-gauge steel is 0.0598” thick. It’s easy to know whether your barricade is high-gauge enough to stand the daily tests of crowds and weather: Just check the weight of the barrier you plan to buy. More weight equals more steel. It’s as simple as that, and it’s the reason SONCO is an industry leader.

So, when our competitors market their “premium” steel barricades made from 18-gauge steel instead of 16-gauge steel, remember: SONCO’s still-affordable, 16-gauge barriers are manufactured from 20 to 25 percent thicker steel, and that makes a big difference!

Check Out the Difference Between 16-Gauge & 18-Gauge Tubing:

Metal Barricades then undergo a hot-dip finishing process, turning them into zinc coated steel barriers protected from rust and ready for inclement weather or rowdy crowds.

Check out this handy, printable chart from Superior Steel Supply when you need to compare steel strength and thickness. And ask a SONCO safety expert for help choosing the barricade gauge that’s best for you!

Mistake 3: “Silver” Barricades Don’t Mean Galvanized

If you’ve been shopping for high-quality galvanized steel barricade products, you know some companies offer powder-coated products painted in “silver” to look like galvanized metal.

Don’t be misled! These silver-coated barricades are often not resistant to rust or corrosion. Once the barrier’s finish is cracked or damaged, rust sets into those areas in no time.

Sure, SONCO sells powder-coated barricades in sleek, branded colors including shiny black for VIP events and orange for pedestrian safety. Our powder-coated metal barriers have a finish that resists damage from cracking, flaking or corrosion. Protect your investment by avoiding that sneaky “silver-powder” coating applied over cheap barrier material.

Mistake 4: Overlooking Hidden Freight Taxes or Misleading Prices

The barricade market is competitive, and our “industry imitators” try to lure customers to their companies through misleading sales tactics.

SONCO’s legacy of service began in 1974 – so we are tough, tried and trusted for a reason.

Remember to read the fine print before going with the “cheapest” interlocking steel barricades you can find. Some companies are lowering barricade prices while drastically increasing freight prices. SONCO Crowd Control Barriers are value-priced, built to be the best in the industry, and include HUGE bulk purchase discounts.

The more barricades you buy, the less they cost. Plus, all galvanized steel barricades are constructed to comply with rigorous OSHA, ANSI and Other safety standards.

Watch this Video to Learn More About Metal Barricades:

Request an Estimate for Steel Barriers

At SONCO, we don’t cut corners or sacrifice product quality for inferior construction methods. That’s why customers in the events, construction, education, medical and public service industries rely on our affordable zinc-coated steel barricades for their events, municipal work sites, construction zones, schools and more.

When it’s time to buy barriers for the most demanding perimeter and crowd control situations, trust the team that has earned your trust. At SONCO, we’re proud to serve you.

Trend now

Theme Park Safety: Avoiding Fines and Accidents with Crowd Control

Learn how crowd control products help keep theme parks safe, avoid accidents, and improve operations. Explore SONCO’s solutions for better crowd management.

Anti Scale Fence for Temporary High-Security Needs

Anti scale fence designed for temporary high-security perimeters, crowd control, protests, and emergency response where standard fencing falls short.

Why Bike Rack Barricades Are the Go-To Choice for Crowd Control

Explore why bike rack barricades are the go-to for crowd control. Learn how these versatile, durable barriers keep events, construction sites, and more organized.